Products

Quality Machinery By

Jyoti Engineering Works

Jyoti Engineering Works is a recognizable name in the competitive field of Soap and Detergent, and we continue to strive for higher quality products and more satisfied customers through our commitment to excellence.

Browse our range of high-tech solutions, and if you have any questions or would like to discuss your specific requirements, please don’t hesitate to contact us. We are here to help you find the perfect solution for your manufacturing needs.

High-Tech Machinery Products

We prioritize our customers’ needs, providing exceptional service and support to ensure their satisfaction.

Our high-tech solutions have met the most demanding tasks and opened up endless possibilities for our buyers. At Jyoti Engineering Works, we have a range of machines suitable for all applications related to the production of Soap and Laundry Products, from development to sizing.

Our Key Offerings

Commitment To Quality

We are committed to providing high quality plants + machinery that meet the needs and expectations of our customers. Our commitment to quality, reliability, & excellent service has earned us a reputation as a top rated manufacturer & exporter of machineries.

Innovation and Sustainability

Jyoti Engineering Works is recognized for its innovative and outstanding plants and machinery used for the production of soaps and laundry. Our approach is focused on driving towards safe and sustainable production through our machines' efficient performance.

High Tech Solutions

yoti Engineering Works offers high-tech solutions for the development of Soap and Laundry Products. Our range of industrial machinery is designed and developed to meet the most demanding tasks and open up endless possibilities for our buyers.

Experience & Expertise

Jyoti Engineering Works has 27 years of experience in the field of manufacturing and exporting machines. Our legacy of 22 years of experience and smart technical know-how has made us a reliable organization dedicated to providing industrial machinery having sound automation & information systems.

Customer Satisfaction

At Jyoti Engineering Works we understand our customer's requirements and work towards providing the perfect solution for their manufacturing needs. Our aim is to ensure that our customers get the best product and service possible, and we are always happy to help with any questions or concerns they may have.

Range of Products

Our comprehensive range of machinery is suitable for all applications related to the production of soaps and detergents, from development to sizing. We have machines like Soap Crutcher, Vibro Sieve, Soap Flaker, Sigma Mixer, Twin Worm Simplex/Duplex Plodder, Triple Roll Mill, Belt/Screw Conveyer, etc.

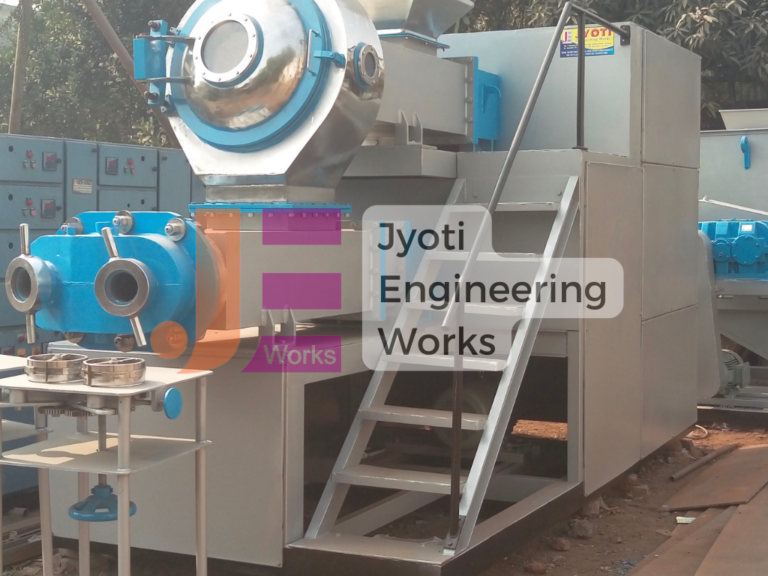

SOAP CRUTCHER

PRODUCT CODE: JEW-01

FEATRUES

- Superior performance

- Low maintenance

- Sturdy construction

- Consumes less power

This is the machine where Gear box and motor drive a screw worm which helps proper mixing of the raw materials used for saponification are mixed and this saponification takes place in this vessels when the materials are heated with steam passed through jacket provided around the vessel. Complete liquid soap is prepared in hot molten condition.

Type 1: Prod: 3 Tonnes | Power: 30 HP Motor

Type 2: Prod: 35Tonnes | Power: 40 HP Motor

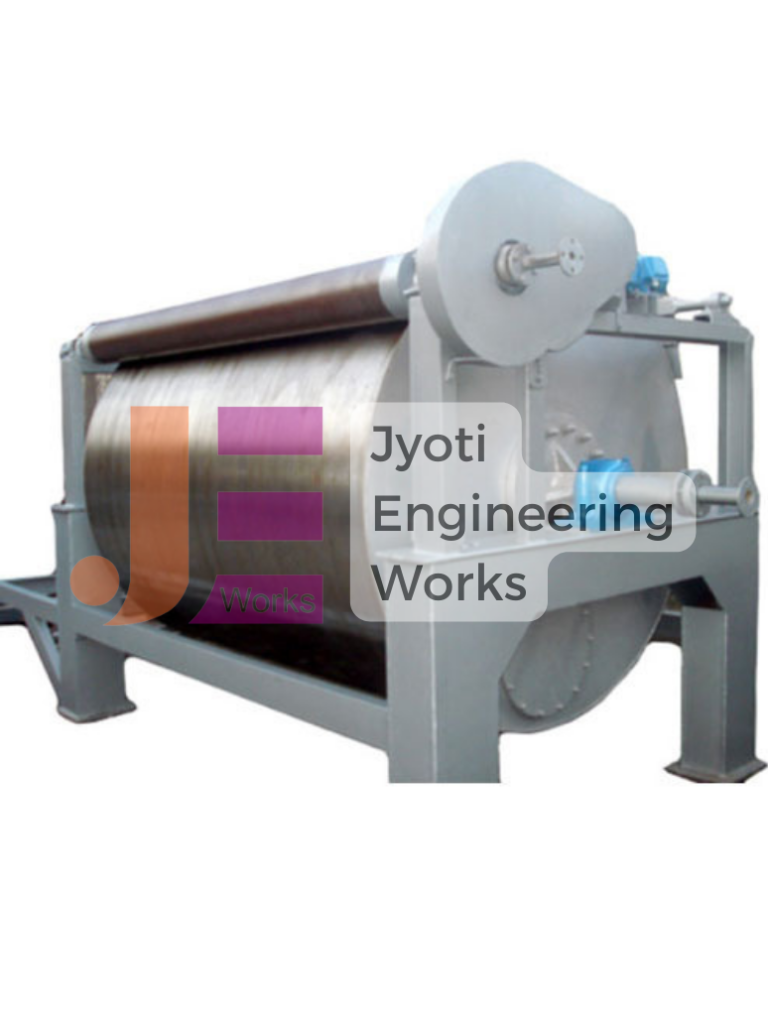

SOAP FLAKER

PRODUCT CODE: JEW-02

FEATURES

- Convenient to install and operate

- Low maintenance

- Available in varied specifications

The type of machine is used to convert the hot molten soap to the solid chips. It has two high quality stainless steel moving drum which is interconnected with chilling plant from which cold water is flown in all around the inner surface of the drum to benefaction a constant heat transmission.

TYPE 1 : Prod. : 500 Kg | Twin : 6” | Power : 10 HP

TYPE 2 : Prod. : 1 Ton | Twin : 8” | Power : 15 HP

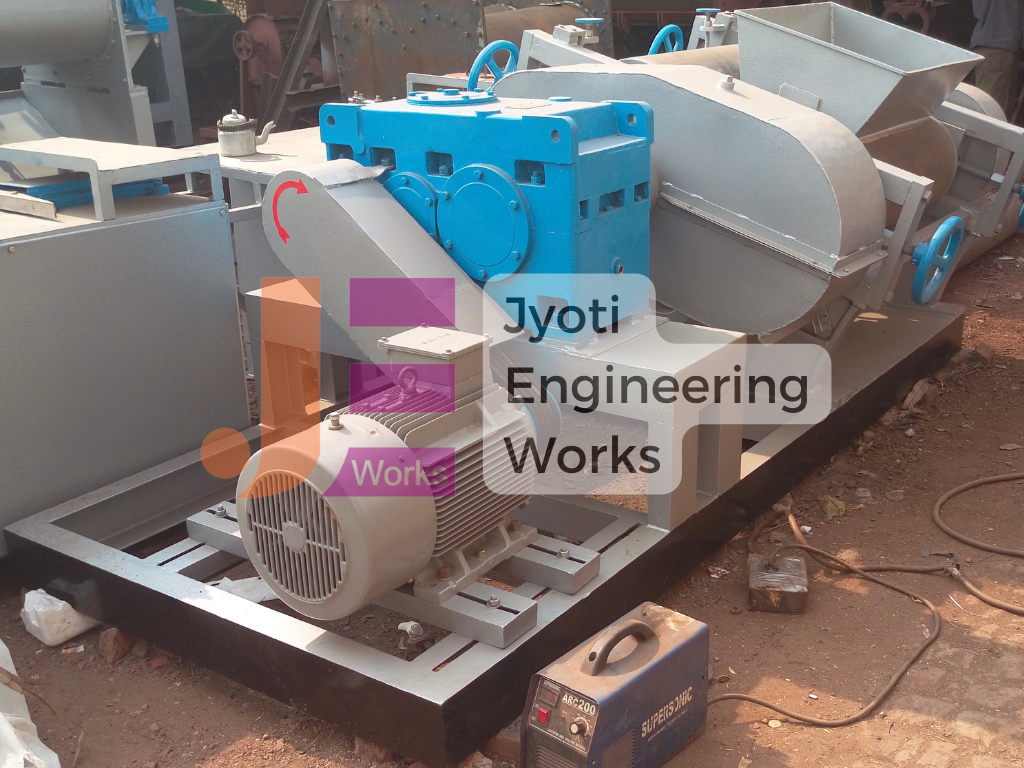

SOAP MIXER

PRODUCT CODE: JEW-03

FEATURES

- Unmatched performance

- Low power consumption

- Long operational life

- High operational fluency

This is a mixing machine provided with the arrangement of two Z- shaped arms which are when rotating, mix the mass (soap Flakes) inside the machine in a dough making manner. In this machine the colour, Perfume, and other kind of filler additives are added and mixed with the soap.

Type 1: Prod: 300 KG/HR | Dimensions: 36″36″Motor: 10 HP, Gear Box

Type 2: Prod: 500 KG/HR | Dimensions: 40″40″Motor: 15 HP, Gear Box

Type 3: Prod: 700 KG/HR | Dimensions: 48″48″Motor: 30 HP, Gear Box

Type 4: Prod: 1 TON/HR | Dimensions: 54″54″Motor: 14 HP, Gear Box

TWIN WORM SIMPLEX NOODLER

PRODUCT CODE : JEW-04

FEATURES

- Strong construction

- High performance

- Robust structure

- Power efficient

After the sigma mixer the mixed mass is passed through this machine where the material is extruded into shape of noodles. In toilet soap and laundry soap production, Soap Pellets Pneumatic Transporting System is used to transport soap noodles. It can connect with soap saponification and vacuum drying plant to make soap noodles, or it can also transport soap noodles to feed soap production line, which can improve efficiency, protect environment and save labours. The transporting ways depends on soap noodles’ position and destination.

Tripple Roll

Product Code : JEW-05

This machine provided with an arrangement of three rolls moving clockwise and anti-clockwise simultaneously. The material after noodle is passed though these rolls and subsequently scrapped into fine flakes form the passed into next machine. Cooling arrangement is also mechanized into rolls.

Type 1 : Prod. : 500 Kg/ Hr | Roll size : 10” x 22” | Power : Gear Box, 10 HP motor

Type 2 : Prod. : 700 kg / Hr | Roll size : 12” x 26” | Power : Gear Box, 15 HP motor

Type 3 : Prod. : 1 tonne / Hr | Roll size : 14” x 30” | Power : Gear Box, 30 HP motor

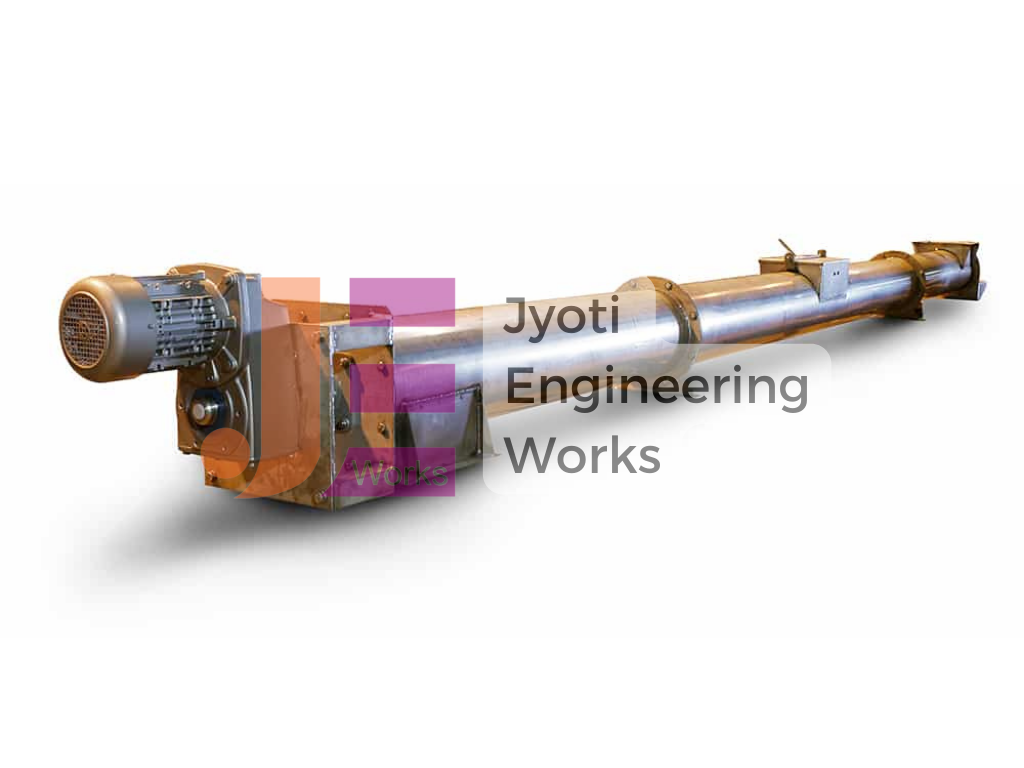

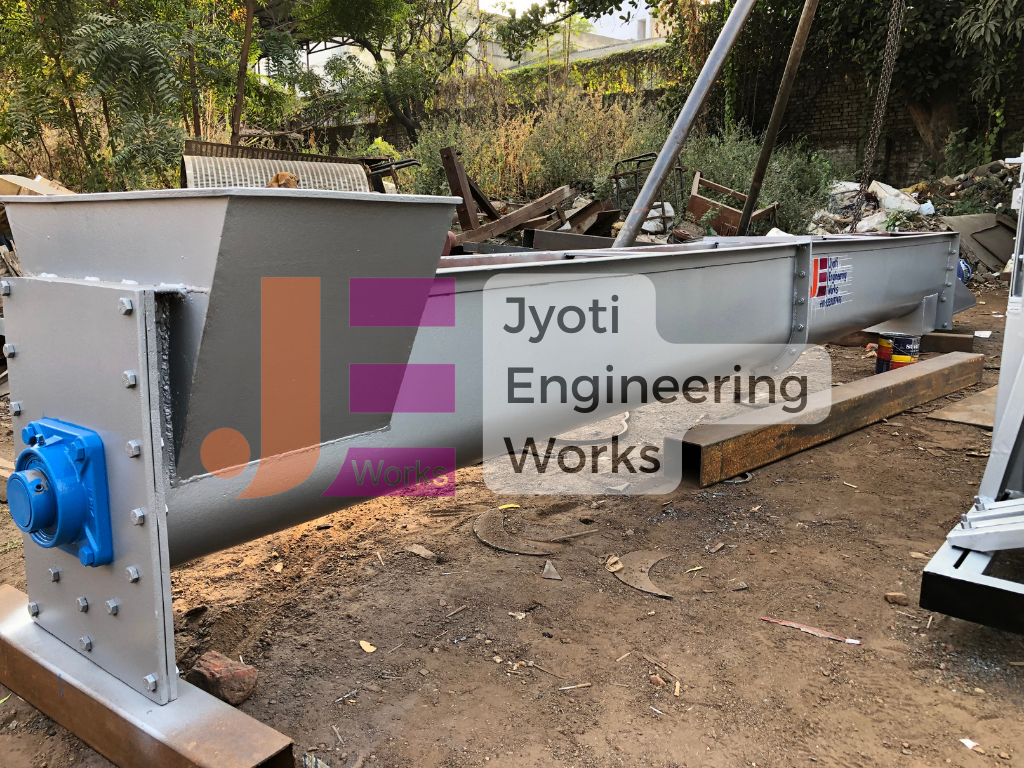

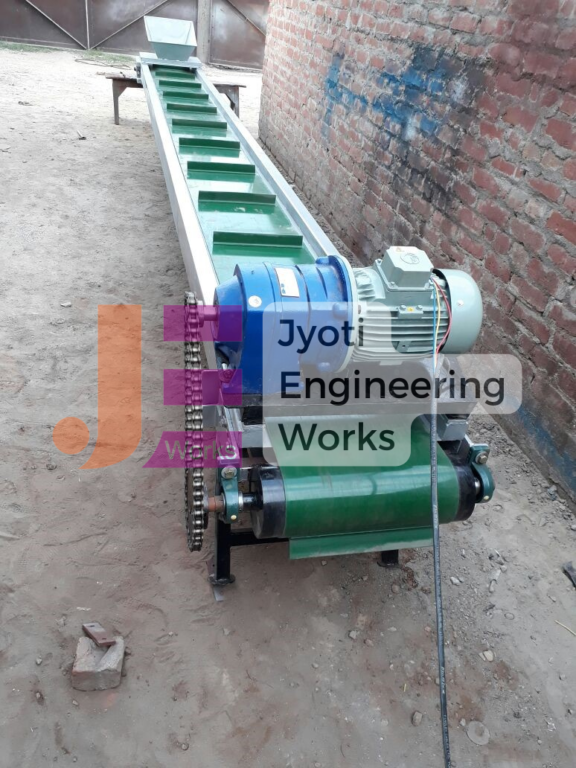

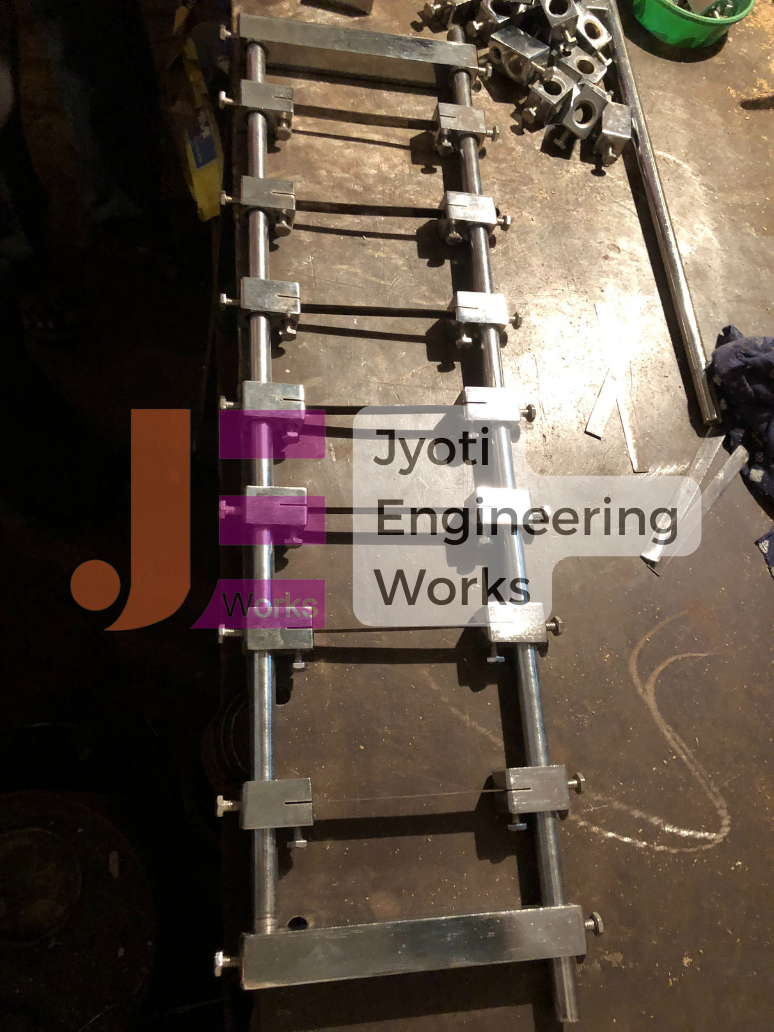

Conveyors

Product Code : JEW-06

Tubular Conveyors

Features :

- Excellent functionality

- Long service life

- Sturdy construction

- Energy efficient

These machines are used to pass the material from one machine to another machine according to the need. It can be transfer of material from roll mill to plodder and from ribbon blender to cage mill.

Type 1 : Prod : 500 Kg- 1 Tonne / hr | Dimension : 12”width x 14 ft length or according to structure | Power : Gear Box , 5 HP motor

Vacuum Plodder

Product Code : JEW-07

Duplex Single Worm vacuum plodder Duplex Twin Worm Vacuum Plodder

FEATURES

- Convenient to install and operate

- Low maintenance

Available in varied specifications

This machine has two stages, driven by independent transmission system. First plodder acts as a simplex refining to make soap pellets in the vacuum condition. In second plodder, soap is pressed and extruded in fine billets through the die or cutter.

Type 1 : 6” plodder | Prod : 500-600 kg per batch/hr | Power : 7.5, 10 HP motor, Gearbox

Type 2 : 8” plodder | Prod : 800-1000 kg per batch/hr | Power : 15, 20 HP motor, Gearbox

Type 3 : 10” plodder | Prod : 1.3-1.5 tonne per batch/hr | Power : 20,25 HP motor, Gearbox

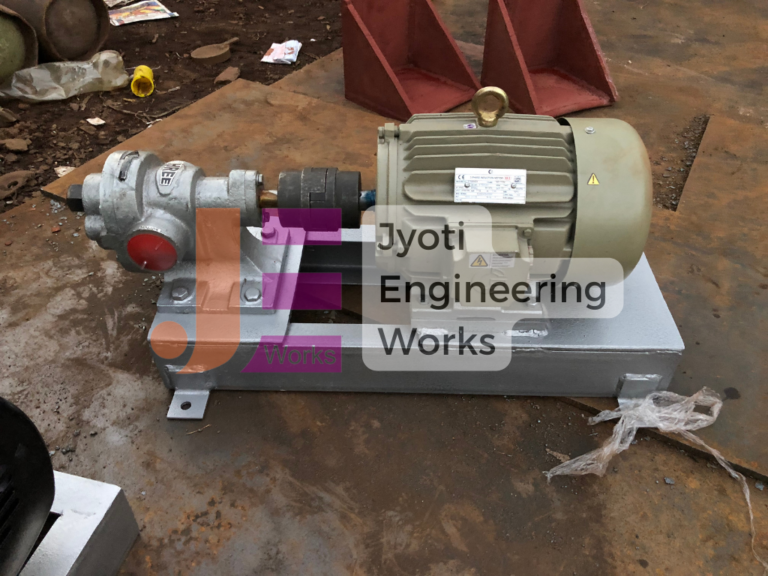

VACUUM PUMP

Product Code : JEW-08

FEATURES

- Convenient to install and operate

- Low maintenance

- Available in varied specifications

Available in varied specifications

This type of gear pump used to generate the vacuum in the vacuum chamber in plodder, which remove the moisture from the soap meshing material. They are one of the most common types of pumps for hydraulic fluid power applications.

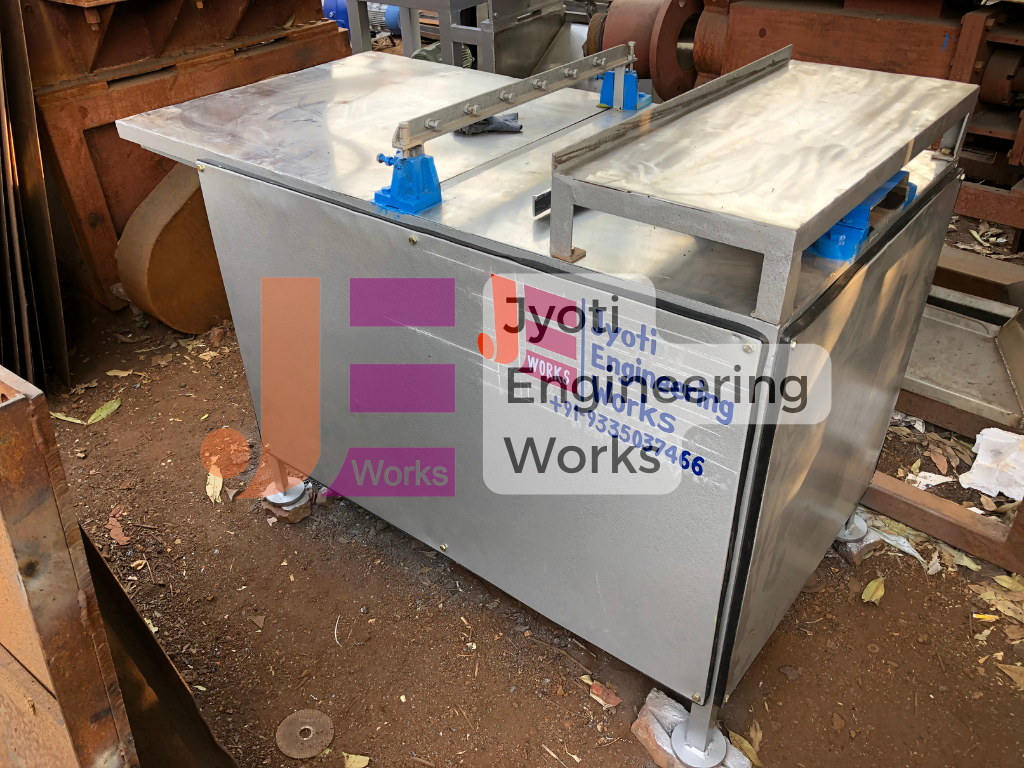

Cake Cutting/dish wash cutting machine

Product Code : JEW-09

FEATURES

- Superior performance

- Low maintenance

- Sturdy construction

- Consumes less power

The long cut bars are passed through machine here they are cut into required size cakes ready to pack with packing machine.

Type 1 : Prod : 1 Tonne | Power : 1 HP motor

Type 2 : (dish wash) | Prod : 1 Tonne | Power : 2 HP motor

Rotary Bar Cutter

Product Code : JEW-10

FEATURES

- High performance

- High cutting speed

- Negligible maintenance

- Sturdy construction

The machine is used for cutting long bar coming from plodder and its rotating cutters are used to stamp the brand name. The speed can be change according to the discharge from the plodder.

Type 1 : Prod : 500 Kg & 1 Ton | Power : Manual.

Foot Stamping

Product Code : JEW-11

This machine is operated manually for stamping soap and detergent cake.

Pneumatic bar cutter and cutting machine

Product Code : JEW-12

FEATURES

- Convenient to install and operate

- Low maintenance

- Available in varied specifications

The automatic soap cutting and stamping machine is used to cut soap bar from the plodder, Cut the soap to billets . and stamp the necessary logo. The primary cutter cut the bars from the plodder at equal repeat lengths. The cutting system works based on the position of the sensor.User-friendly system to vary lengths of bars. Bars are conveyed to cutting and stamping machine through a conveyor. The bars are sensed automatically and pushed forward for secondary bar cutting and stamping.

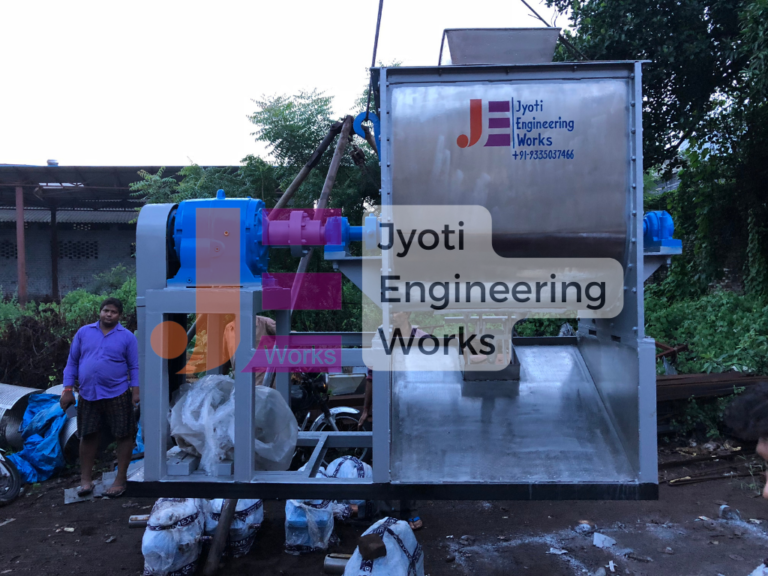

DETERGENT POWDER PLANT

Product Code : JEW-101

Ribbon Blender

FEATURES

- Energy efficiency

- Robust construction

- High performance

- Longer service life

This machine is provided with the arrangement of specially designed twisted Blades to perform best results of power mix within a ‘U’ Shaped design through. All the mixing ingredients are dropped from the top of the mixer inlet as per their sequence of addition and after mixing the whole batch is dropped though the bottom side either mechanized gate or manual openable gate.

Type 1 : Prod : 100 kg per batch/10 min | Power : 5 HP motor, Gearbox

Type 2 : Prod : 200 kg per batch/10 min | Power : 7.5 HP motor, Gearbox

Type 3 : Prod : 300 kg per batch/10 min | Power : 10 HP motor, Gearbox

Type 4 : Prod : 500 kg per batch/10 min | Power : 15 HP motor, Gearbox

Cage Mill

Product Code : JEW-102

FEATURES

- Power efficient

- Robust design

- Strong construction

- Negligible maintenance

This is a machine used for changing the size of the material to uniform size. This machine is used to remove big useless particles of sand or dust. The material is provided as the requirement of the customer (M.S or S.S). There is also a perforated sheet to provide uniform size.

Type 1 : Prod. : 100 Kg / 10min. | Dimension : 14”x30” | Power : 5 HP

Type 2 : Prod. : 300 Kg/ 10min. | Dimension : 16”x36” | Power : 7.5 HP

Type 3 : Prod. : 500 Kg/ 10min. | Dimension : 18”x36” | Power : 10 HP

Type 4 : Prod. : 1000 Kg/ 10min. | Dimension : 24”x36” | Power : 15 HP

Powder Storage Vessel

Product Code : JEW-103

FEATURES

- Convenient to install and operate

- Low maintenance

- Available in varied specifications

This storage vessels is used to hold the solid batch materials before dropping them into Mixer. This vessel is conical in shape and has a manual/pneumatically operated butterfly valve at the bottom which is used to discharge the material into the Mixer when required. Before discharging the material, the butterfly valve holds the material within the Batch holding vessel. Capacities are matched with Mixer.

Bucket Elevator

Product Code : JEW-104

FEATURES

- Convenient to install and operate

- Low maintenance

- Available in varied specifications

This machine has buckets attached with the chain in rotating motion, which are used for transferring powder from one level to another or where we need to take powder from lower to higher level.

Vibro Sieve

Product Code : JEW-105

FEATURES

- Convenient to install and operate

- Low maintenance

- Available in varied specifications

This machine is used for sieving the oversize content in the powder materials. And it also helps in removing the plastics, iron or it may be rocks. After this the final powder passes to the automatic packing machines. . The Material is fed from the top center to screen finished where the undersized material passes through the screen to discharge chute and oversize material is collected through the tangential chute aside.

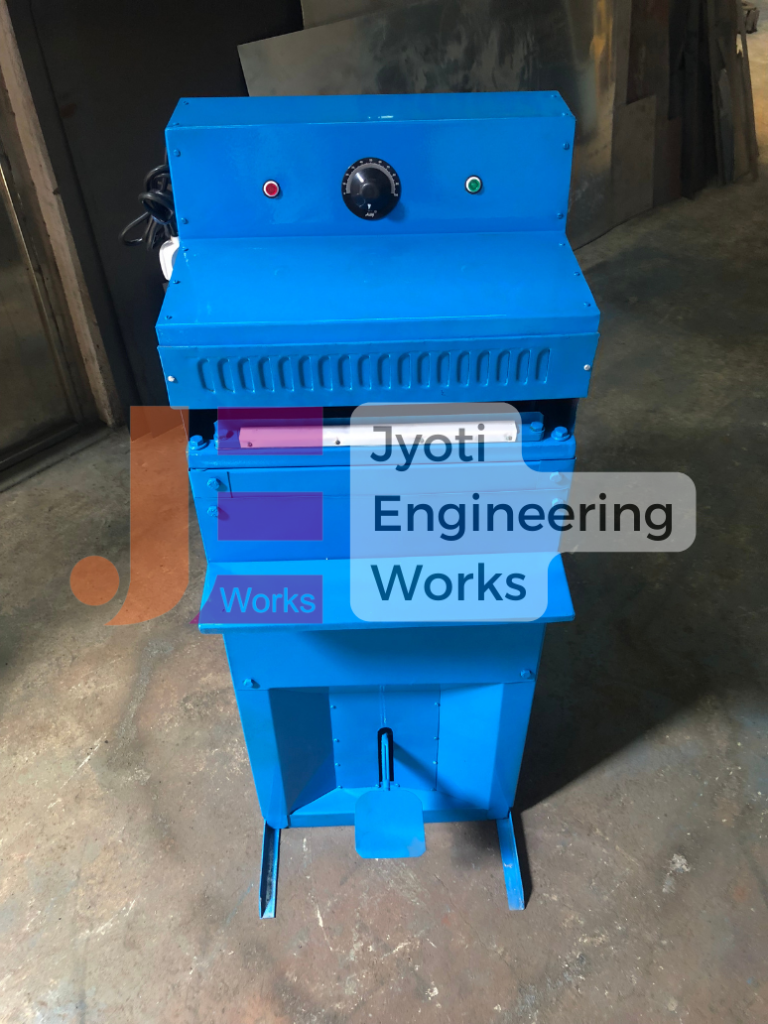

Manual Paddle Sealer

Product Code : JEW-106

FEATURES

- Convenient to install and operate

- Low maintenance

- Available in varied specifications

This machine is used for Sealing powder Plastic Pouches / Bags manually.

Testimonials

What Our Client’s Say

"We have been working with Jyoti Engineering Works for several years now and have always been impressed with their commitment to quality and innovation. Their plants and machinery are top-notch, and their team is always available to provide exceptional service and support. We highly recommend Jyoti Engineering Works to anyone looking for reliable and efficient manufacturing solutions."

"As a small business owner, I was hesitant to invest in new plants and machinery. However, after speaking with Jyoti Engineering Works, I knew they were the right choice. Their team was patient, knowledgeable, and helped me find the perfect solution for my manufacturing needs. I am extremely satisfied with my purchase and would highly recommend Jyoti Engineering Works to anyone looking for high-quality and affordable industrial machinery."

"Jyoti Engineering Works has been an incredible partner for our company. Their plants and machinery have exceeded our expectations, and their team has gone above and beyond to ensure our satisfaction. Their dedication to safety and sustainability is impressive, and we appreciate their commitment to the environment. We highly recommend Jyoti Engineering Works to anyone looking for innovative and reliable manufacturing solutions."